Development

- Experienced development and engineering team

- Use of state-of-the-art simulation software

- Development of the best technical and commercial solutions for customers

- In-house tool development

- Expertise in component assembly

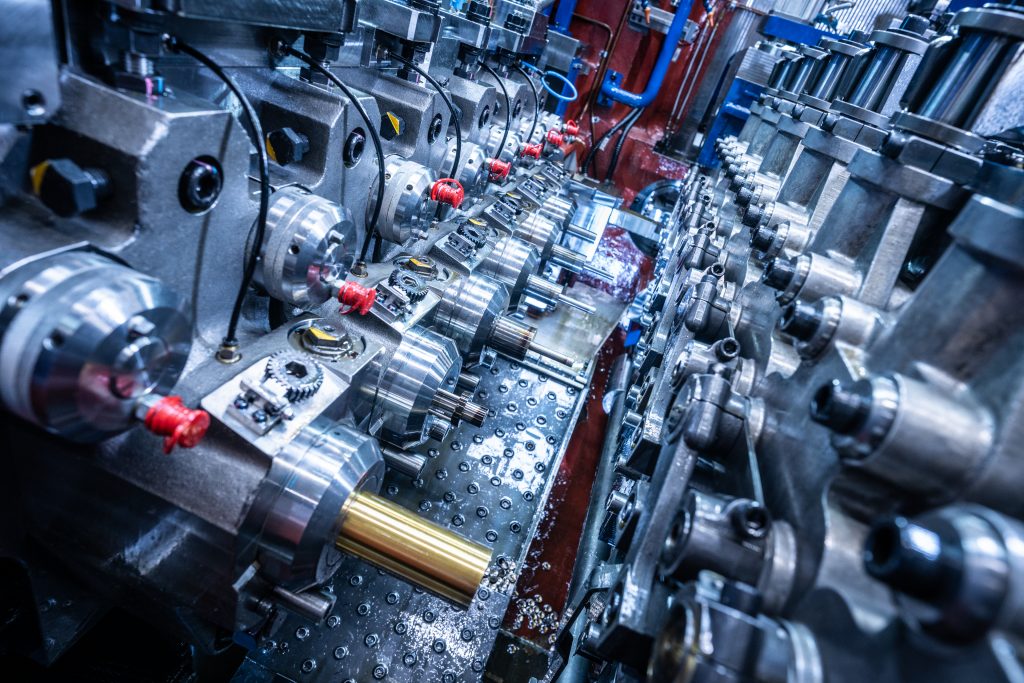

Cold forming

- 5–6 stage presses including servo technology

- 130–900 t pressing force

- 15 cold forming machines

- Fully automated processes

- Production from wire, blanks, and billets

- Forming of steel, aluminum, and copper

Further processing

- Bending, coining, punching, trimming, stamping, radial riveting, setting, and testing

- Resistance welding and laser welding

- Fine washing, vibratory grinding, and isotropic superfinishing (ISF®)

- Fully automated assembly (from wire to finished product)

- Part marking with laser-engraved DMC

- Fully automated inspection systems with packaging in customer-specific containers

- Investment solutions based on quantity

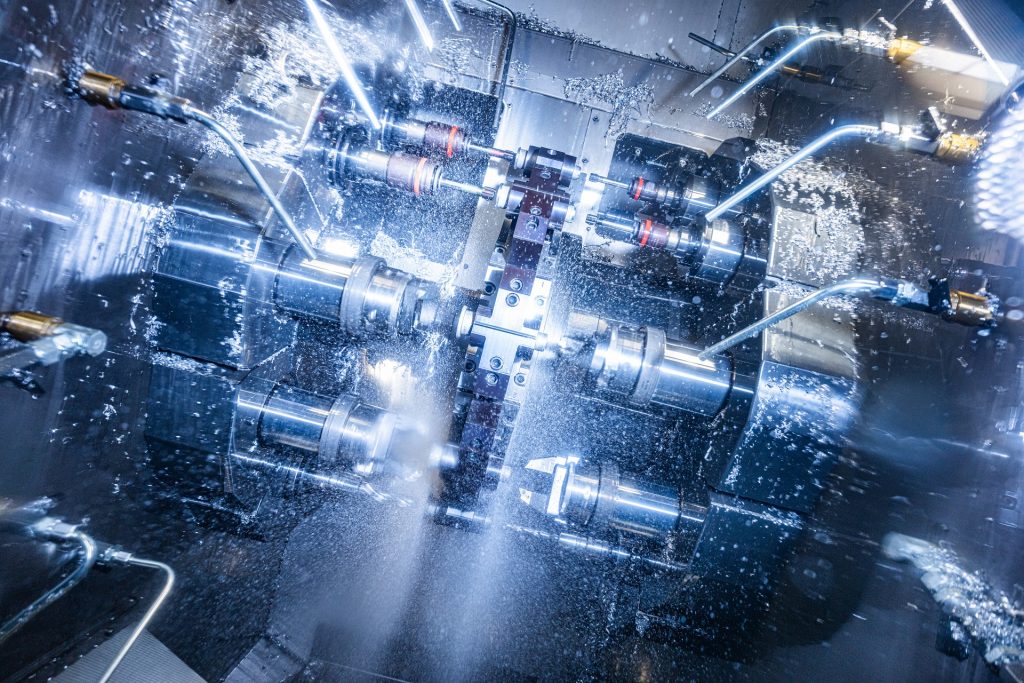

Machining

- Turning, milling, reaming, grinding, thread forming, and thread cutting

- Use of proprietary feed systems

- Single- and multi-spindle machining centers with integrated optical measuring systems

- Fully automated processes due to process expertise, including 100% inspection

- Interlinking all the way through to packaging for high quantities

- Option of machining from bar material in prototype construction

Toolmaking

- In-house toolmaking with a high degree of flexibility

- Expertise in tool production and optimization

- Prototype construction

- Production of feeding systems and spare parts

Logistics

- Packaging according to customer requirements

- Development of customized logistics solutions for global projects

- Worldwide cooperation with logistics service providers to ensure customer proximity and flexibility

Sustainable value creation is our business!